Eye on manufacturing

Manufacturers, subcontractors and suppliers

Welcome to our vibrant world of endless possibilities, where innovation meets quality in every product we offer. With a diverse range of over 8000 unique items (excluding textiles), our catalog transforms into tens of thousands of options, thanks to various size and color variations. Each product tells a story, crafted by dedicated creators, and brought to you with care and passion.

At the heart of our operations are the remarkable individuals and manufacturers who create the backbone of our supply chain. We meticulously source semi-finished products, raw materials, and materials, all skillfully printed and produced in our state-of-the-art facility in Helsinki.

Allow us to introduce one of our flagship products: lanyards. Annually, we import, store, print, and distribute approximately one million lanyards to our customers in Europe, and the United States. Sourced from skilled manufacturers in Dongguan, China, our lanyards boast exceptional quality. Every thread is woven with precision, sewn by experienced hands, and shipped to our warehouse via ocean freight. From the initiation of the order to reaching your doorstep, this process takes about three months, ensuring you receive only the finest products for your events.

There are many steps to making lanyards, from dyeing yarns to weaving and sewing

Our commitment to quality extends to every aspect of our business. Lanyard clips, essential components of our products, are manufactured with unwavering consistency and excellence at the same factory location. This meticulous approach guarantees that every batch meets our stringent standards.

We take pride in our association with reputable manufacturing facilities, audited and approved by industry giants like McDonald's®, The Coca-Cola® Company®, Disney®, and Sedex®. We prioritize transparency and accountability, annually visiting these factories to gain firsthand insight into the manufacturing process. This knowledge enables us to develop products responsibly, ensuring your satisfaction while respecting our environment.

In our pursuit of sustainability, we're transitioning from standard polyester lanyards to eco-friendly alternatives. Our commitment to the environment is reflected in our move towards recycled plastic lanyards made from RPET material. These lanyards, crafted from recycled plastic bottles, signify our dedication to reducing our ecological footprint.

Regardless of the advancement of printing technologies, screen printing lanyards is still manual labor

Another highlight of our collection is our extensive range of festival wristbands. From Tyvek® wristbands ideal for short events to durable vinyl wristbands suitable for multi-day festivals, we offer choices that cater to various needs. Partnering with renowned manufacturers like Brady, we guarantee wristbands that meet international standards and adhere to stringent safety regulations. Brady is a multinational publicly traded company specializing in identification products and various labeling products. The wristbands are ISO9001 and ISO13485 certified (BSI) and Brady's factories have also been audited by Sedex®.

Whether for festivals, theme parks, or hospitals, our wristbands are crafted from safe and tested materials, ensuring peace of mind for all our customers.

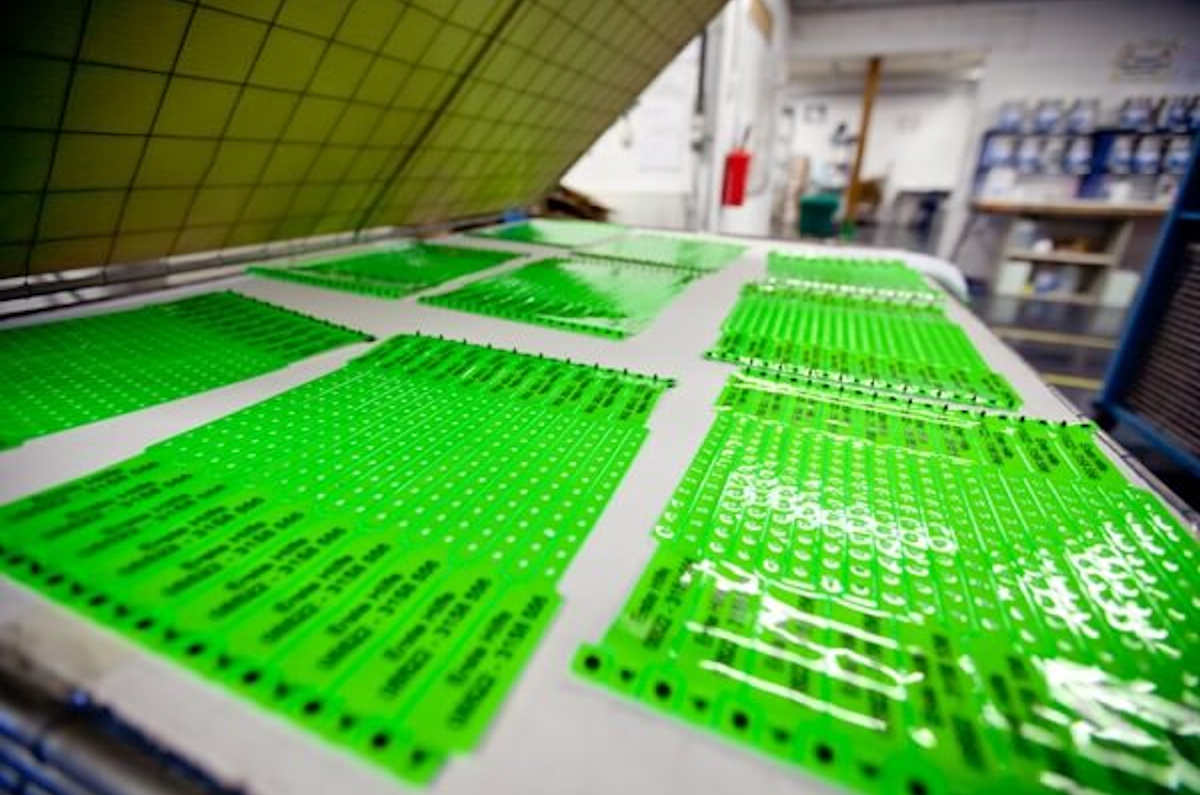

Wristbands are also printed using screen printing

At our core, we believe in direct engagement. By working closely with manufacturers worldwide, we understand the intricate journey of our products, from conception to delivery. This hands-on approach enables us to offer unparalleled expertise, exceptional customer service, and timely deliveries.

When you choose us, you're not just purchasing products; you're investing in a legacy of knowledge, experience, and dedication. Welcome to a world where quality meets innovation, and your satisfaction is our utmost priority.