Our sustainability

Introducing Pinpops: Pioneering Sustainability in Every Print

Our expansive 16,000 sqft production facility epitomizes our commitment to eco-friendly operations. We have significantly reduced our energy consumption through strategic upgrades, such as replacing traditional luminaires with cutting-edge LED lighting and harnessing the power of district heating during chilly winters. Our modern, energy-efficient premises exemplify our dedication and serve as a testament to our vision for a greener tomorrow.

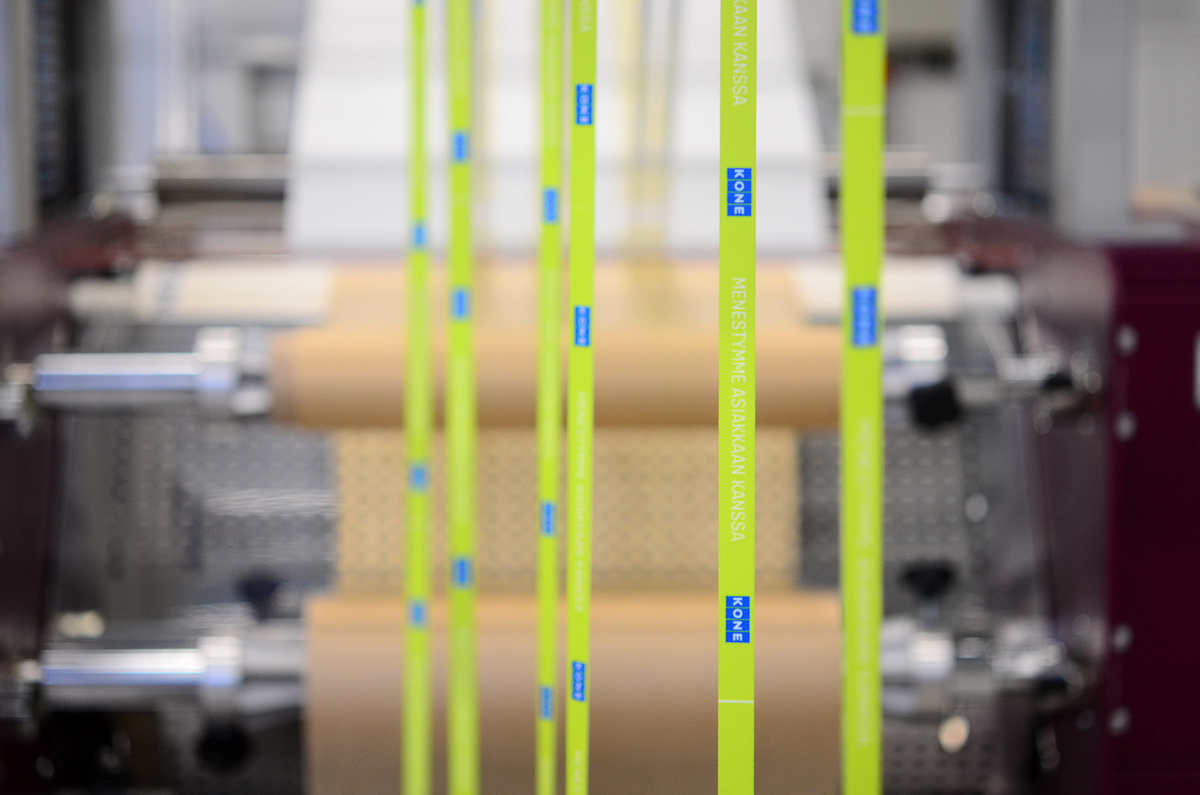

Incorporating natural light into our workspace, courtesy of large, full-height windows, fosters a comfortable environment and diminishes our reliance on artificial lighting. Coupled with our investment in state-of-the-art printing presses designed for minimal waste, they showcase our unwavering commitment to energy efficiency and environmental preservation.

The large windows of our production building provide plenty of natural light

In a significant stride toward sustainability, we are transitioning from conventional polyester lanyards to RPET lanyards crafted from recycled plastic bottles. Considering our vast reach - selling over one million lanyards annually across the United States and Europe - this shift embodies the impactful change that arises when scaling sustainable practices.

Oeko-Tex® certified non-toxic inks support responsible production

At Pinpops, sustainability isn't just a goal; it's our driving force. Join us in our journey toward a greener, more responsible future—one print at a time.