Trusted manufacturing

A supply chain built for quality, consistency, and speed

Our catalog includes thousands of products and variations — built for events, brands, and organizations that need reliable delivery and consistent quality.

Behind every item is a real production partner. We source raw materials, components, and semi-finished goods through a trusted supplier network we’ve built over years, then manage customization and quality control through proven workflows.

Lanyards are a good example of how we operate: multiple vetted manufacturing partners, predictable lead times, and planned replenishment so popular styles stay available. The goal is simple — you get the right product on time, without surprises.

Lanyard production involves multiple controlled steps — from yarn preparation to weaving and assembly — handled by experienced manufacturing partners

Quality isn’t just about the print — it’s also the hardware, stitching, and consistency from one production run to the next. That’s why we work with partners who can hold tight tolerances and repeat results at scale.

We prioritize manufacturers with established compliance practices and third-party audits, and we continuously monitor performance across batches. The result is fewer defects, fewer surprises, and a smoother experience for customers working on fixed event dates.

We’re also expanding recycled-material options where they meet performance requirements — including RPET lanyards — while keeping the same standards for durability and delivery reliability.

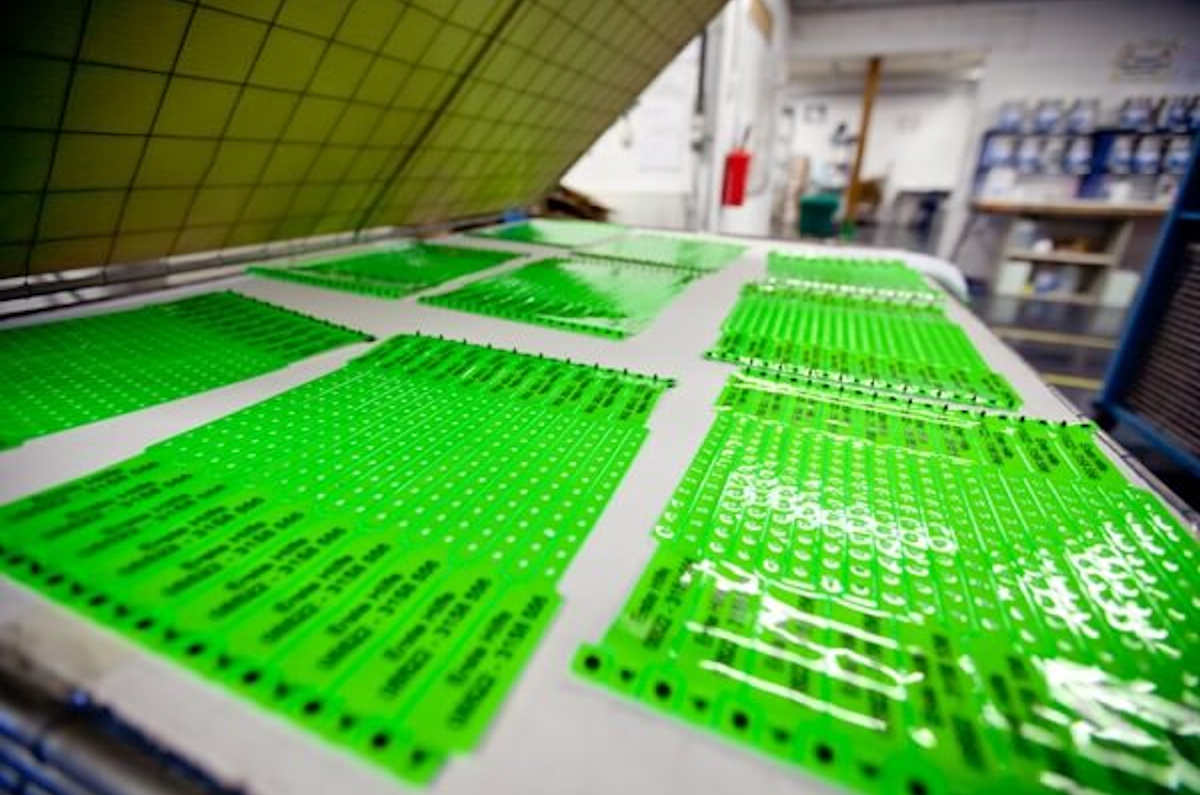

Screen printing lanyards still relies on skilled manual work to ensure consistent quality and detail

Wristbands are another high-volume category where supply chain matters. We source from multiple proven manufacturers so we can match the right wristband type to the job — from Tyvek® for short events to durable vinyl options for multi-day use.

We prioritize partners with strong quality systems (including recognized ISO certifications where applicable) and tested, safe materials — because wristbands are worn all day and need to perform reliably.

Just as important: we plan production and inventory around event schedules, so customers can count on consistent lead times and dependable delivery.

Wristbands are screen printed by trusted partners using proven methods for durability and repeatability

We work directly with manufacturers around the world and keep tight control of specifications, materials, and production methods. That visibility helps us solve problems early, maintain consistency, and keep lead times predictable.

For customers, this means a stronger supply chain: better product consistency, reliable timelines, and the ability to scale when you need volume. If your deadline matters, our partner network and process discipline are exactly why choosing Pinpops makes life easier.